Wood Works & Steel Stands

by Karen Knapstein

When deciding how to build a shed, several factors should be considered regarding the type of construction to use. What’s the shed’s purpose? How big will it be? Are there environmental factors? (Salty sea air or tidal surges? Will the shed be in an earthquake area?) How fast does the shed need to go up?

Wood frame construction is still the predominant method of single-family home and homestead construction in the U.S. As a renewable resource, wood is easy to work with and economical. For hundreds of years, it’s been the first choice of builders.

With that being said, it’s important, too, to take a look at the increasing popularity of framing with steel. While framing with steel accounts only for a minute percentage of new low-rise construction, it is growing. We’ll look at a few reasons why building with steel makes sense, too.

Stud Frame: The Tried And True

Stud wall framing with wood is tried and true. Consumers trust it. The American Wood Council, in its publication “Details For Conventional Wood Frame Construction,” said, “History has demonstrated the inherent strength and durability of wood frame buildings.” Most people are familiar with the traditional 16- or 24-on-center wood stud-framed construction method. It doesn’t take a lot of time, manpower, or equipment. Using studs to frame remains popular because people are most familiar with it. Just two people can build walls and stand them up and get them ready to roll. They can set the trusses on top of the sill plate and build a building without large equipment.

Modern post-frame design prevents rot by keeping wood away from the soil.

Courtesy of Sharon Thatcher

There’s no argument that stud framing is a good choice for small-scale sheds. But let’s explore a couple other options.

According to recent census data, wood framing is still the preferred construction method for single-family residential housing. As the gaps narrow between steel and wood prices, as steel is recognized as an ecologically responsible material to build with, and as builders are educated about the medium, a larger percentage of new buildings are sure to be erected with steel framing.

Cold-Formed Steel: Up & Coming

A recent announcement from the Steel Framing Industry Association points to the growth of steel framing:

“Led by strong performance in the volume of structural cold-formed steel framing products, total manufacturing volume of cold-formed steel framing stud and track increased in the third quarter of 2019 from 295,961 tons to 297,193 tons, according to the latest Quarterly Market Data Report released by the Steel Framing Industry Association.

Structural products, typically used for load-bearing applications such as exterior walls, lateral force-resisting systems, floors, and roofs, reported a 5.8% increase in manufacturing volume.” [cfsei.memberclicks.net]

This particular ag building project is one of the biggest Wick Buildings has completed in the last 20 years. Designed to hold bulk cottonseed, the shed itself is 99′ x 200′ with 25′ eave height. While most of their buildings take one to two trucks to deliver all the posts, trusses, and other components, this building took nine trucks to deliver everything.

Photo courtesy of Wick Buildings

Larry Williams, executive director of the Steel Framing Industry Association (SFIA), said using cold-formed steel to build sheds is a good choice: “With a shed, you’re going to have more exposure to things that will degrade a product, like water and bugs. Cold-formed steel is ideal in an environment like that.”

BuildSteel.org lists five top reasons why cold-formed steel is a superior choice for construction: It’s cost-effective, durable, sustainable, non-combustible, and easy to install.

1) Cost-effective

Due to manufacturing efficiencies and incorporating recycled steel in the process, cold-formed steel studs now only cost about 30% more than wood studs. While they cost a bit more, there is very little waste with cold-formed steel. The quality is consistent and it’s a very predictable product. Steel studs and track don’t warp, twist, or shrink like wood. Every piece is straight and true and stays that way, which makes the construction process easier.

2) Durable

Cold-formed steel is impervious to pests like termites and other insects; it’s resistant to corrosion and mold. Williams said some studies have shown the typical zinc coating will protect the steel from corrosion for up to 1,000 years. “For a shed, the coating on the studs is generally heavier than what’s used inside, so it may last longer,” he added.

3) Sustainable

“Steel is the most recycled material in the world,” said Williams. Cold-formed steel is 100% recyclable, which will make it a more appealing choice to some customers. All cold-formed steel contains recycled content; plus, at the end of a steel-framed building’s product life, the steel components could once again be recycled.

4) Non-combustible and resilient

According to the Steel Recycling Institute, cold-formed steel has the highest strength-to-weight ratio of any building material. It’s non-combustible and resistant to extreme environmental and seismic loads.

5) Easy to install (after the learning curve)

Cold-formed steel studs and tracks are lighter than dimensional lumber, and straight components mean corners are square and walls are straight. Williams said, “There’s a little bit of a learning curve when you first start using it. But, I universally find that people who build with steel — once they get through the learning curve — prefer it to working with other framing material and methods. It’s always straight and it’s extremely consistent.”

An additional thing to note if considering venturing into building with metal studs: If the shed is to be heated or cooled, a thermal break may be necessary because metal conducts cold much better than wood.

Big Results With Post-Frame

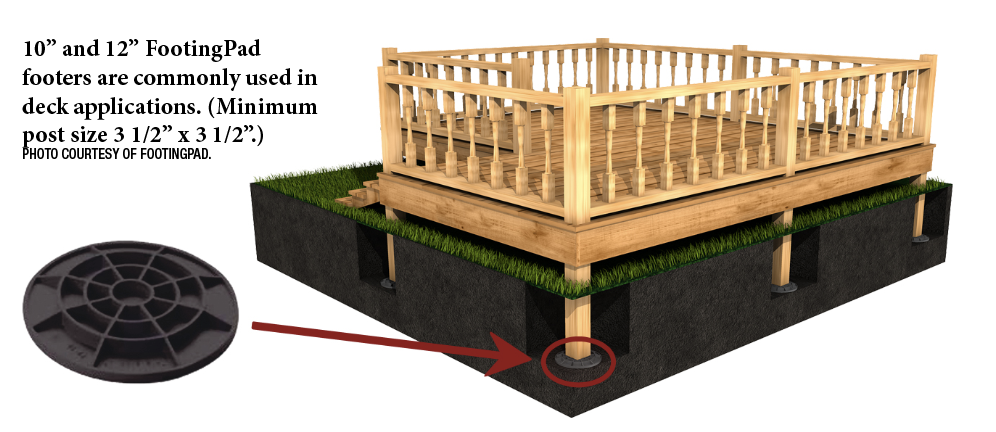

In a nutshell, post-frame construction uses large posts buried in the ground or mounted on a foundation as a vertical structural support; girts fastened between the posts provide horizontal support. The posts in post-frame can be 8′ or more on-center.

There’s a learning curve when getting started with cold-formed steel, but many builders prefer it once they’ve gotten through the curve. Courtesy of Steel Framing Industry Association

Post-frame buildings used to be seen as temporary, said Elmer Sensenig of Richland Laminated Columns. The bottoms of the wood posts would rot in the ground and the buildings would fail. Sensenig said you need three things to rot wood: moisture, bacteria, and oxygen. “If you take one of those elements away, your wood won’t rot.” Nowadays, the standard practice is to mount the posts on the foundation or poured concrete wall, or use a barrier on the part of the post that is in the ground, such as GreenPost, or use a product like Perma-Column (a concrete column on which the post is mounted). The posts don’t budge and they won’t rot.

The benefits of building with post-frame include quick construction times and lower construction costs. An experienced two- or three-man crew can easily have a post-frame shell erected in just three days.

Post-frame suits large sheds. The structural design allows for clear spans up to nearly 100′. You can construct much higher walls due to the larger structural members. And, there is often a need for large wall openings to accommodate moving equipment in and out of the building in agricultural, suburban, and equestrian buildings. Since the walls of post-frame structures are not load-bearing, there are no limitations for door size or placement.

Of course, the post-frame components can get big. And the trusses — really big. Handling the larger material can require much heavier equipment than the saw, hammer, and other hand tools needed with standard wood stud framing.

Heavy-Duty Heavyweight

One construction method we don’t hear much about is joisted or load-bearing masonry. This labor-intensive construction method requires stacking concrete blocks, bricks, or similar material, and the floors and roof are constructed of wood or steel. The materials are readily available, the walls go up quick, and cinder blocks are somewhat cheap. Using this type of construction for a building is quite labor-intensive. But, if your client is in the market for a storm shelter for their homestead, this may be the way to go.

Getting Started With Steel?

Want to learn more about building with cold-formed steel? Larry Williams, executive director of the Steel Framing Industry Association, recommended starting at www.buildsteel.org. The website has good information and resources about how to get started, basic framing methods, and information about tools and equipment that you might want as you get ready to start using steel. For a list of places where you can buy steel, visit www.cfsteel.org; search the member directory for “Suppliers.”