Whether you’re building a deck, boardwalk, or pavilion, a structure is only as good as its foundation. When building structures with posts set in the ground, proper anchoring will prevent the settling caused by the weight of the structure on the subsoil, by footer degradation or decay, or by upheaval caused by water freezing in the ground. The last thing you need is for your customer to tell you someone tripped and was injured on the deck or boardwalk that you built – and that they think it’s your fault. Or that the pavilion you built is now crooked because the posts have settled unevenly. Here we will discuss how some products are used to combat footing failures.

Stable Footing

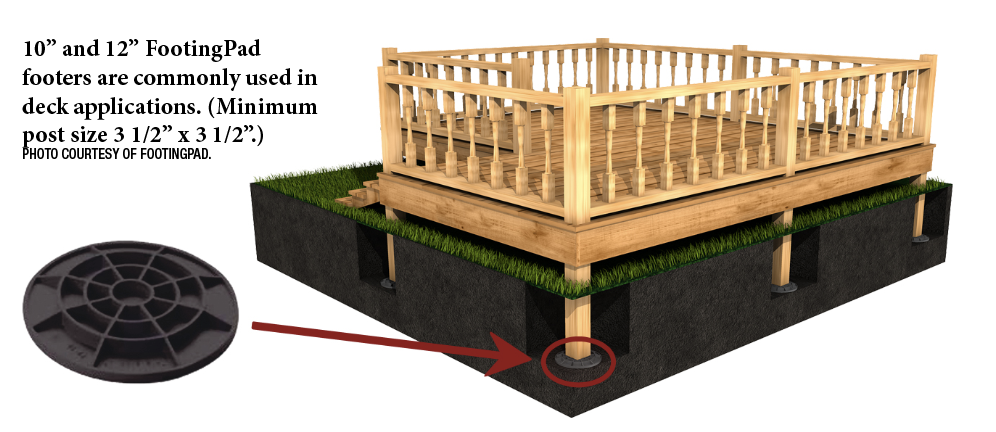

In order to carry a load without failing, load-bearing posts must have a solid footing. FootingPad (www.footingpad.com) is a composite isolated footing system that has been designed to replace concrete footings beneath load-bearing posts. The product was developed by Glen George and Jerry Eckhoff. Through their experience in post-frame construction, they determined using concrete as an under-post pad was “overkill.”

Made from a proprietary composition of engineered polypropylene (100% recycled) and fiberglass, the footing pads are molded with a rib pattern that effectively transfers the weight carried by the post to the supporting soil beneath the pad.

Paul Kluempers, General Manager at AG-CO, the company that manufactures FootingPad footers, explained, “By expanding the surface area the pad carries more load. The effectiveness of the pad has nothing to do with the concrete or the material. The pad works because it’s stronger than the soil. Concrete isn’t a bad footing – it’s just harder to work with.”

FootingPad footers are lightweight and strong, making them easy to work with. They also won’t rot or degrade. “Our footers are made from an inert material. There’s very little change over time with the product. In general, it’s resistant to any kind of environmental impact. Microbes and moisture in the soil are not going to break it down. It will last for a very long time.”

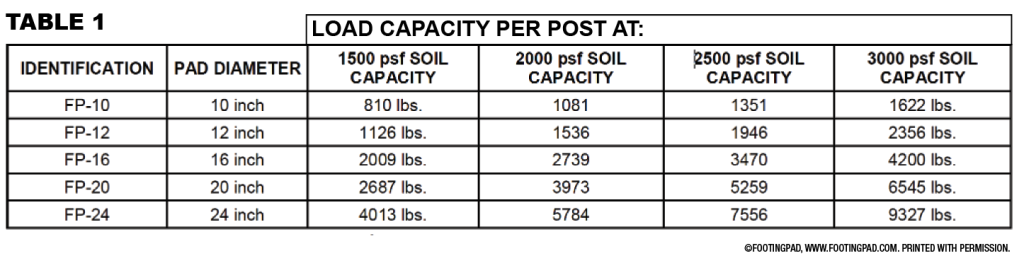

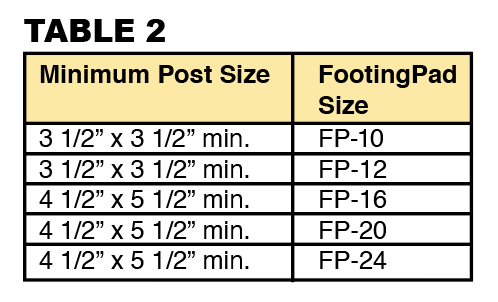

They are made in five different sizes running from 10”-24” diameter to accommodate varying loads. FootingPad footers can be used with any type of post, including pre-cast concrete. The footers with 10” and 12” diameters are most frequently used for building decks. But determining the size needed is more complicated than that. “There are three factors that work together to determine the size of footing needed,” Kluempers said. “The weight of the structure (load) [see Table 1], the soil type, and the post size. Any time you’re talking about stability, these three things are important.”

One caution Kluempers gave was to follow the product guide [Table 2] for the minimum size post to be used. “Too small of a post on a big FootingPad and the post can punch through the pad [if the load is heavy enough].”

A footer beneath the post expands the surface area so the post can carry more load without sinking. When the soil fails to bear the load, the post pushes through the soil and the load moves.

FootingPad has met ICC-ES standards and received certification (ICC-ESR-2147). Through third-party product testing, it was found in compliance with both the International Building Code and the International Residential Code.

Perma-Column — Not Just For Post-Frame

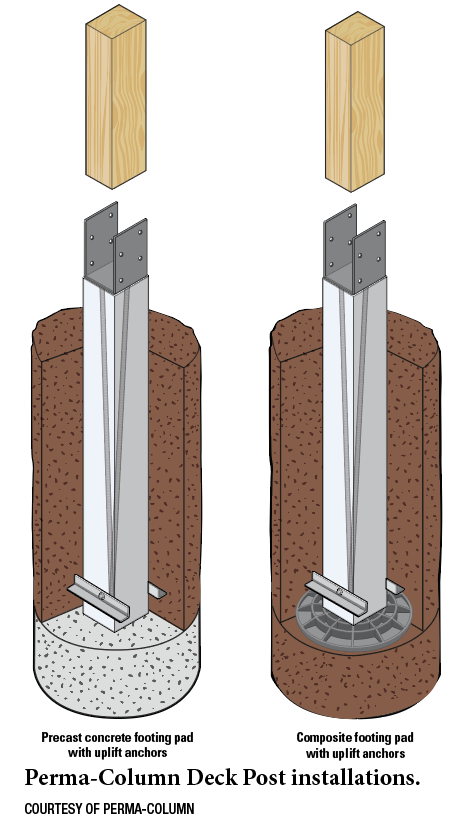

Perma-Column® (www.permacolumn.com) precast concrete deck posts eliminate the need for ready-mix concrete, plus they keep the wood out of the ground to eliminate the eventual rot that occurs when wood is buried. “Wood is elevated out of the ground via a steel bracket atop a precast concrete foundational pier,” explained Perma-Column President Mark Stover.

“The design benefits builders by eliminating the hassles of pouring concrete on the jobsite, making deck construction quicker and more efficient. Since you don’t have to wait for concrete to cure, you can, conceivably, build a deck in a day and move on to your next job.”

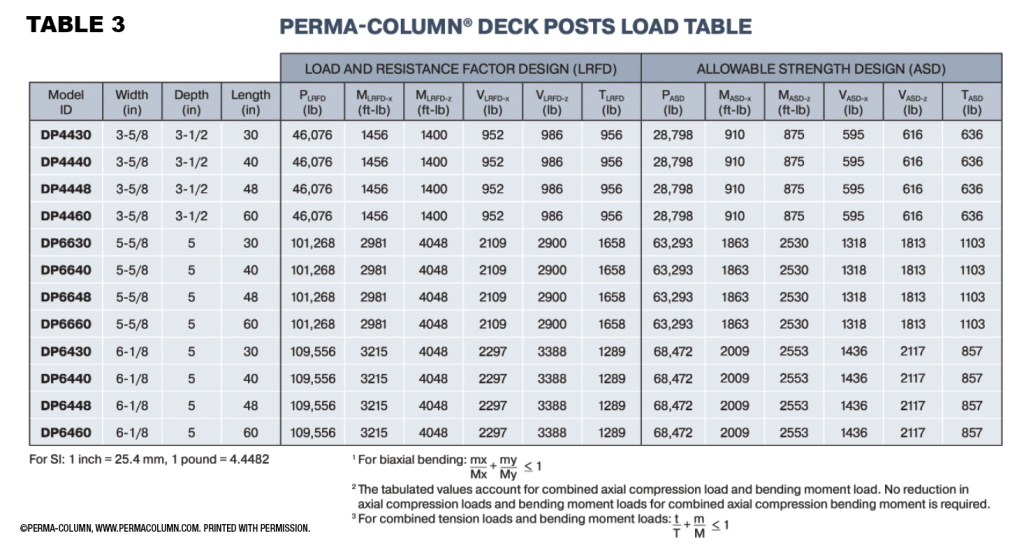

The patented design combines precast concrete with 60,000 psi rebar reinforcements and a welded, powder-coated ¼” steel bracket to which the wood post attaches. Since the Perma-Columns are precast, they can bear weight immediately.

To prevent uplift, brackets are bolted near the bottom of the concrete base. The company’s uplift anchor options are 2” x 2” x 8-1/2” or 2” x 2” x 12” galvanized angles, which are attached using galvanized Grade 5 bolts, nuts, and washers.

To accommodate builds in all climate zones, Perma-Column manufactures its concrete deck posts in 30”, 40”, 48”, and 60” lengths. “Our deck posts come in various sizes; which one you should use depends on the frost line. When you’re putting in a deck, the code inspector will come out and measure the hole to make sure it’s deep enough to meet the frost line requirements,” he said.

Builders can be satisfied these concrete posts will pass muster. Like FootingPad, Perma-Column has earned an ICC-ES certification (ICC-ESR-4237). “This certification confirms our efforts to provide the highest-quality product to the deck builder,” said Stover. “Builders can work with the confidence that our deck products will meet national and international code requirements.”

GreenPost Stays Put

PlanetSaver Industries (http://www.planetsaverind.com/) manufactures the GreenPost, a unique product well suited to supporting outdoor structures. Posts are treated against decay and pests, and they’re specially notched to resist uplift. Then a specialty coating is applied.

PlanetSaver’s Barry Hoffman explained the problems that builders have been seeing and how the GreenPost helps solve those problems: “What we’re hearing from builders is after 8 or 9 years of being in the ground, treated posts are seeing some rot.” Degradation of the wood is caused by microbes and moisture in the soil. Rot typically happens in the “decay zone” (2” above grade to 6”-8” below grade, depending on the soil; this is the area where microbes thrive thanks to the moisture and oxygen levels in the soil.

Notches in the buried ends of GreenPosts prevent wind from pulling the posts out of the ground. Up to a 72” barrier can be applied to GreenPosts.

Photo courtesy GreenPost/PlanetSsaver

The GreenPost process creates an impermeable double barrier that keeps the wood treatment chemicals inside the wood and moisture and pests away from the wood. The double barrier consists of a water-based asphalt emulsion plus a layer of polyethylene, which then goes into an oven at over 600 degrees for a heat curing process. “We’re retaining the treatment in the post, therefore adding more protection and the post is lasting much longer. From a preservative standpoint, that’s the benefit.”

PlanetSaver also manufactures a polyethylene sleeve that can be applied by builders to posts sourced elsewhere. It’s as stable as the wrap that’s applied to the GreenPost. You only have to apply the wrap to the area of the post that will be in the decay zone.

“It took about two years to develop the composition of polyethylene that we came up with,” Hoffman said. “It’s very similar to the polyethylene blend that’s used in landfill liners, which last about 100 years.”

If using sleeves they have the flexibility of being positioned anywhere on the post so you have between 2”-6” above ground for proper protection required for it to be effective.

“Once you put the post sleeve on, you don’t have to worry about the post destabilizing because of rot. The only thing you have to worry about is what happens to your post above the ground,” said Hoffman.

How deep the posts are buried (or where the wrap is applied in the case of PostSaver) depends on the location and the application. “Some areas, like in upstate New York, is 50”. The majority of the country is 48”. It varies by jurisdictions and geography.” (Up to a 72” barrier can be applied to GreenPosts.)

The offset notch system seen on the GreenPost is patented. “We had to do testing to see how good it was,” Hoffman said. “With uplift notches you can just put the post in the ground and pour 16” of concrete and it’s much stronger than the alternatives. Builders would either nail blocks at the end of the post to prevent uplift or drill holes into the post at offsetting degrees and put ½” rebar in the holes to prevent uplift. We found our uplift notches were almost twice as strong as either of those other two alternatives,” he said. “Nails would pull out of blocks or rebar would bend. With the notches, the concrete has to fail in order for the post to uplift.”