While sheds vary significantly in their size and intricacy of construction, from simple open-sided huts covering bicycles or tools to large structures with shingled roofs, windows, and even electrical outlets, one of their main objectives is protecting what’s inside them. To do this, they need to stick around. While it’s difficult to give an exact time for the expected lifespan of sheds because many factors can affect it, what follows are tips on how to give them a long, successful life.

Better Materials for a Long-Lasting Shed

Shed life expectancy comes down to the materials used in its construction; avoid substandard materials. “We focus on buying high-quality materials and cover that with a high-quality paint job,” said Dean Wengerd, owner of Cherokee Structures, Chuckey, Tennessee.

Certain materials used on sheds will help them last longer than others. However, in general terms, according to information provided by Malden, Massachusetts-based Urban Sheds Inc., expect the following lifespans for the most common types of shed materials:

• Wooden sheds such as those used for wood storage: 20-25 years

• Vinyl sheds: 25-30+ years

• Resin sheds or plastic sheds: 5-7 years

• Metal sheds: Less than 5 years

“Choosing the materials for your shed is an important part of creating a long-lasting outdoor structure,” said Rachel Hudson, associate segment marketing manager, LP Building Solutions, Nashville, Tennessee, which makes the well-known LP SmartSide siding. “We advise using a durable siding product with a great warranty. Structures using engineered wood … can provide superior resistance against termites and fungal decay while offering exceptional aesthetic value.”

Justus Eaton, CEO, Alpine Buildings LLC, Mocksville, North Carolina, said that materials are probably the most important aspect of the shed. “I purchased a shed years ago and within a few years from the purchase date, the trim was swelling out so much,” he said. “It looked like someone had taken a nail punch and punched the nails deeper into the trim. I could literally rip off some of the trim with my bare hands.”

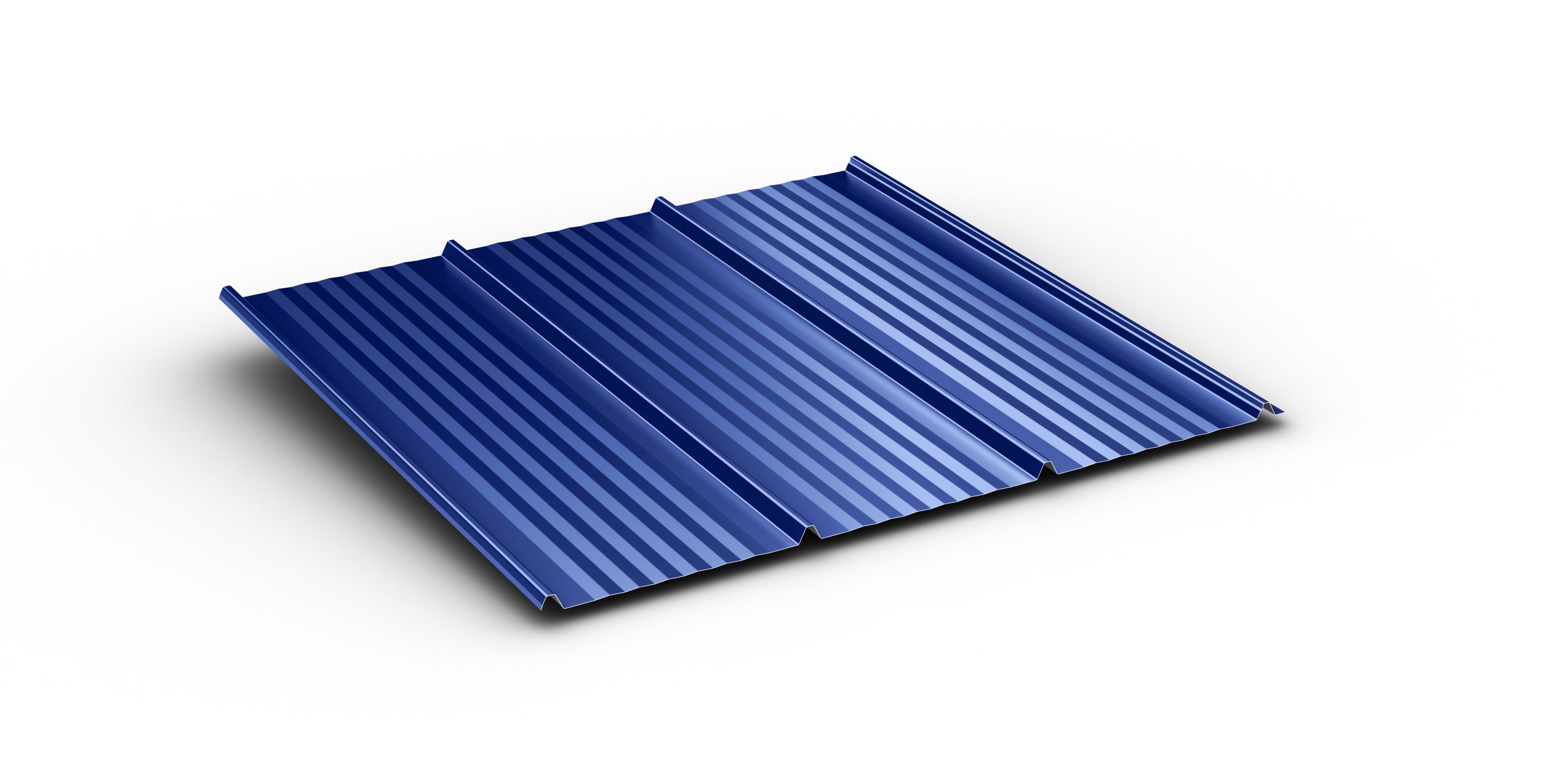

Also acknowledging the importance of materials, Amanda Tharp, product manager at Arrow Storage Products, Breese, Illinois, said that it can come down to a “durable versus all-weather strength” decision. “Fabric buildings are durable and can stand up to the elements,” she said. “However, all-steel buildings are naturally more rugged due to their construction materials. Wooden sheds are also durable but more expensive. Arrow Storage sheds are made from Galvalume steel with a highly anti-corrosive aluminum and zinc plating. These steel sheds are built to last.”

Foundation and Location

To ensure longevity and avoid damages, the shed must have a solid foundation. Tharp said make sure the shed is installed on a flat and level surface. Hudson cautions, “[Sheds] sitting directly on the ground can expose sheds to excessive moisture conditions. Products such as LP SmartSide Trim and Siding require a minimum of 6″ clearance from finish grade (ground cover).”

Pick the best pad material (wood, gravel or concrete) for the shed. Paving slabs can also be an appropriate alternative for the base. Anchor the shed properly to avoid damage from improper drainage or unstable ground.

Many municipalities dictate the shed foundation choice. Local code often spells out exactly where sheds can be placed, as well as suitable foundation options, required footer depths, and more. Shed foundation requirements tend to vary based on the size of the building, the intended use (stricter codes often apply for habitable buildings), and the local climate. Check local requirements before choosing final shed foundation.

Shed location is important; it’s crucial that the shed has protection against extreme weather conditions such as heavy rains and high winds. If you live in an area that experiences heavy snowfall, place sheds where they won’t be under extra snowfall from surrounding vegetation and trees. Make sure that spot isn’t at a high risk of flooding. Put the shed in a spot where it will be the least vulnerable to high winds or heavy rains, and protected from the sun and big trees to reduce everyday wear and tear from the elements. Tharp said fallen limbs can shorten a shed’s lifespan.

While warranties are a big push in the shed industry, Matthew Black (of Blacks Buildings, website MyShed.io, and education platform Shed University) said the shed itself, and the components used to make it, are seldom the cause of call-backs related to shed warranties. “Rather, sagging and leveling issues are usually the cause of problems later, and often it’s because the homeowner wants to place the shed in a place where it doesn’t belong.”

His company offers a good warranty for a shed seller: lifetime on workmanship, and decades-long warranties for parts like metal roofs. When the company sells a shed, though, Black said it stresses that the sagging and leveling issues are not covered by the warranty.

Quality Workmanship

The successful craftsmanship and installation of a shed affect its long life. Eaton said that “while the installation isn’t as critical as the materials themselves, that doesn’t negate its importance. Making sure that all the materials are attached as designed is very important.”

Prolonged water exposure is a bane to sheds’ existence. This is especially so with wooden sheds because wood expands and contracts when it absorbs moisture. Because of this, making sure the roof and walls are attached and sealed properly is very important. If wooden sheds are sealed correctly, the seal acts as protection from weather. “[This means] screwing metal with long enough screws, sealing the LP SmartSiding with caulk at every lap, and nailing it on the studs per the recommended standards,” Eaton added.

“A lot of times builders do not properly flash horizontal trims, therefore reducing the lifespan of the product because it is not properly sealed,” Hudson said. “Products such as LP SmartSide Trim installed horizontally require a proper flashing be installed over the top edge to help prevent moisture intrusion.”

Implementing quality control during shed installation will not only ensure its long life but also will help prevent callbacks. Easton said having an in-depth, multifaceted, quality control process is the last defense against any possible things that might have been missed. “Having one designated QC can help create consistency and also helps to set the expectations that must be met by the manufacturing team.”

A Dynamic Design

Can a specific design actually boost shelf longevity? Yes, Tharp said, asserting that “classic styling combined with materials and finishes designed for long-term outdoor use are the key to a long-lasting shed.”

From a design standpoint, one of the most important aspects of a shed is the doors. “If they aren’t designed correctly, there will be gaps in the top and bottom of the doors,” said Eaton. “Over time, this could allow moisture to get inside of the shed. Another common mistake is the way the doors are framed. Some companies will frame their doors with the 2″ x 4″s all flat instead of having some framed on edge as well. This creates a much more rigid door and doesn’t allow them to warp nearly as quickly.” GSCB