An Indiana Warm Floors heating technician connects PEX tubing to a manifold. Photo Courtesy of Indiana Warm Floors

In-Floor Radiant Heat A Solid Choice For Concrete

By Karen Knapstein

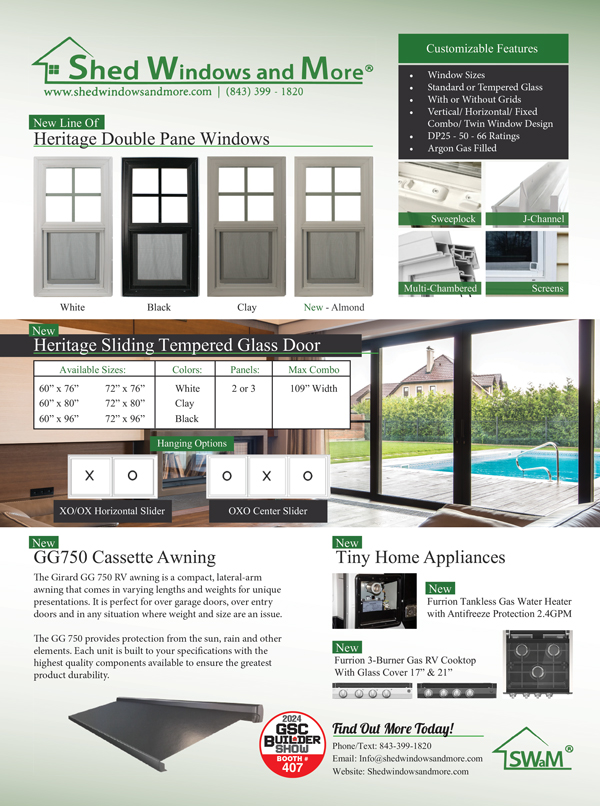

Radiant floor heating systems are efficient and effective ways to heat garages, driveways, patios, commercial buildings, farm structures, and sheds. Indiana Warm Floors (IWF) of Angola, Indiana, provides just about everything a contractor needs to install an in-floor radiant heating system in a single kit.

Scott Patton, engineer and owner of Indiana Warm Floors, said you first have to determine the type of in-floor radiant heating system that is most appropriate for the building. He said if you’re heating a small shed or single-car garage, “sometimes it makes sense to hook up an electric cable system, which would be connected to a power thermostat that turns on when it calls for heat.” Additionally, if the building owner’s utility company offers time-of-use rates, it can further reduce the cost of running the system. Discounted time-of-use rates allow the concrete floor to be heated during off-peak hours, which saves energy dollars compared to heating at peak electric rates.

If building a larger shed, it’s more economical in the long run to install a cross-linked polyethylene (PEX) tubing system with a central boiler. The boiler system can be heated with natural gas, electricity, or wood/coal.

Patton’s company fabricates radiant heating systems for any type of residence, commercial building, or agricultural building. But to build the right system, Patton said they need information that includes the square footage of the building and the region that it’s in. They also need to know the type of insulation and R-value so they can calculate the heat loss and how many BTUs are needed. Higher R-values requires fewer BTUs to maintain the heat; they adjust a system with a lower R-value by setting the temperature higher or putting heavier cable in.

An IWF electric radiant heating kit includes the cable system, CAD layout, and a thermostat that has the capacity to switch the power to the cable on and off.

A hydronic kit includes the PEX tubing and CAD layout, manifold(s), and the boiler module that also has all the necessary components: Circulation pump, air vent, expansion tank, and pump control. The number of manifolds needed depends on the number of temperature zones required; the number of circuits is determined by the size and layout of the floor to be heated. Both types of kit include any special tools needed.

Installing An Electric System

Patton said the typical installation involves the concrete contractor forming up a slab like normal. He leaves the sub-grade or gravel 2” lower than normal to allow for high-density 2” foam to be installed on the sub-grade. The electric heating cable is a commercial grade, heavy-duty cable with a plastic covering to protect it from the corrosive elements in the concrete. The electric cable is attached to the foam or wire mesh, usually 4” on center to get the proper heat output. “At that point the installing contractor will take an ohm reading of the electric cable to verify the cable is fully intact and operational before they pour the concrete,” Patton said. “The reading needs to match the label that is on the cable.” Once that’s verified, the concrete pad is poured.

After the concrete cures, an electrician hooks up the line voltage thermostat. The thermostat gets its power directly from the breaker panel; when the thermostat calls for heat, it lets electricity go through to the cable in the floor to warm the floor to the desired temperature.

Installing A Hydronic System

In a hydronic radiant floor heating system, warm water circulates through flexible PEX tubing placed within the concrete floor. During installation, the PEX tubing, which has an oxygen barrier to prevent corrosion, is laid out 12” on center and attached to the foam or wire mesh. The tubes are tied together in a manifold and connected to the boiler module. The combi-boiler module is connected to the water so it can provide shower water.

The PEX tubing matrix is tested to 100 psi air pressure to make sure there are no breaks in the tubing or connections; it’s kept under pressure until the final connection. The concrete is then poured. Keeping the system pressurized through the concrete pour verifies that the PEX tubing isn’t damaged during the pour.

The concrete is allowed to cure for 10 days. After curing, the PEX matrix is hooked up to the boiler and operating system. When the radiant system is filled, additives to prevent corrosion to the system are also added; air is removed via the auto air vent.

When a hydronic in-floor radiant heating system’s thermostat calls for heat, it turns on the circulating pump; hot water then circulates from the boiler through the tubes in the floor, heating the concrete. The boiler is set to heat the water to 110 to 120°F, which will heat the slab to about 80 to 85°F.

As far as an installation timeline goes, Patton said typically the electric heating cable or PEX will go down in one day; the concrete is poured and cured (10 days); and then setting the boiler module can be set in a day. “With a cable it’s not a big deal – you just wire it up,” he said. “With a boiler, we prebuild the boiler module so it installs quickly. It helps us do jobs a couple states away. We prebuild the system and just go do it and connect it.”

Selling Points

There are several selling points a contractor can share with their clients when discussing the possibility of installing an in-floor radiant heating system. The benefits of in-floor radiant heat include quiet, healthier indoor environmental quality (no dust or allergens blowing around), no ductwork, and no floor vents. Radiant floor heating can work under any floor covering, including carpet, tile, hardwoods, and linoleum.

Also, heating the floor rather than the air makes living and working spaces more comfortable with less energy, which means reduced heating bills. Patton said, “It’s so popular because it’s so energy efficient and easy to control. Your energy bill is 20% lower because you’re not heating up the air that gets lost,” he said.

Additionally, he said the price of an in-floor heating system is exactly the same as a furnace with ductwork. “If they add ductwork in addition to in-floor radiant heat to accommodate cooling, then it runs $4 to $5 per square foot extra.”

Avoiding Common Mistakes

Patton said in some jurisdictions a special permit is needed. Contractors should keep in mind that they may need an inspection before the concrete floor is poured to make sure the system is set up properly and to make sure it’s holding pressure.

When asked about common installation mistakes, he said allow the full 10-day curing time for the concrete. “There can be problems if you add heat to the cure.”

He also said they like to encourage that the cable or PEX tubing is installed in the slab 12” or 18” from the outside edge so it doesn’t encourage heat loss around the outside of the foundation.

When the relief cuts are sawed in the concrete, he advised not to saw too deeply to avoid hitting a line. Floors are typically 4” of concrete on top of either PEX tubing or electric coil; normally a relief cut, of about 1-1/4”, is sawed, that allows the concrete to have a controlled crack as it dries and cures so it doesn’t randomly spider crack. No additional relief cuts are needed with in-floor radiant heat, he said.

Also, if the building is carpeted, a cheap, fluffy pad should not be used because it inhibits the heat flow. It’s recommended that a commercial pad that’s a little denser and conducts heat better should be used.

Patton said it’s a mistake that builders don’t promote in-floor radiant heating. “The clients will see an article in a newspaper or magazine, and they’ll say it makes a lot of sense. They tell their builder, but the builder isn’t promoting it,” he said. “Most of the time they see it as an add-on or extra option. The young builders that want to set themselves apart – they’ll mention cool stuff like in-floor heat to their clients. And they might end up with a job.”

Most people like the comfort and control that an in-floor radiant heating system affords. It may be within your power to give your customers the comfort and control that they’re looking for. GCSB