Sometimes a shed owner will need a surface option that is easier on the feet than wood or concrete. This is where recycled rubber products, such as Unity Surfacing Systems, might be a valid option.

Unity Surfacing Systems’ pavers are manufactured using 95 percent recycled material. All of Unity’s interlocking unitary rubberized safety surfacing, flooring and paver products are made with tire buffings and crumb rubber granules recycled in-house and mixed with a clear urethane. The Splash Design and solid TPV/EPDM top tiles and pavers can be manufactured using diverse color combinations resulting in unlimited design potential.

Unity manufactures surfacing products from 1/2” thick to 4” thick. What the building will be used for will determine the thickness and type of paver that should be installed.

Company spokesman Erick Prinz had the Unity pavers installed in his own driveway. He explained this product “provides a soft, durable surface that is confortable to stand on yet durable for foot-traffic, equipment and machinery.”

When asked about what specific products would best be used in sheds, patios, and porches, Prinz recommended using the 1/2” or 3/4” thick material in sheds because it is lightweight and can be glued down to the sub-base. “For patios and porches I would recommend the 1”, 1-3/8” or 1-3/4” as these are interlocking, which allows them to stay together during temperature related expansion and contraction issues when installed outside.”

Ease Of Installation

He said when installing indoors, any level sub-base with little to no stress cracks or gaps will work well. “If the pavers are installed wall-to-wall, it doesn’t need to be glued,” he continued. And it’s suitable for use with in-floor radiant heating.

But there can be exceptions. For example, if the building is a storage shed where equipment is going to be dragged and jockeyed around, stressing the tiles, the tiles or pavers should be glued down so it doesn’t move and bubble.

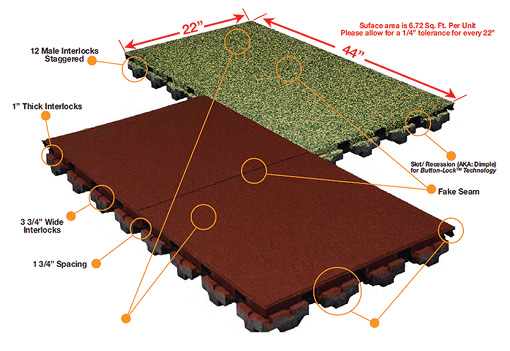

Unity Surfacing Systems offers pavers that lock together, making them easy to install and easy to create interesting floor patterns for customers. Photos Courtesy of Unity Surfacing Systems

“Contractors like the way they interlock,” Prinz said. “Installation is very easy for contractors and it’s a very good upsell for them. We do sell a 1” interlocking tile and a 1-3/8” tile. Both of those products interlock and you don’t need glue with those. They’re thicker and come in at a more premium price. For installers, it’s an additional upsell from the 1/2” or 3/4” material,” he said.

The fake seam in Unity pavers make laying out floor patterns easy. If installed indoors, wall-to-wall, the pavers don’t need to be glued.

Plus, the pavers have a flexible double tile design that makes creating interesting finished floors easy. It has a fake seam down the middle that makes creating a “step and repeat” pattern simple for those customers who would like a little added visual interest. “The tabs make it easy for placing tiles in different patterns. There are two types of tops that customers can choose from: either brick face, or tile top so it looks like standard tiles,” said Prinz.

Outdoor Use

Prinz said Unity Surfacing Systems are a good choice for outdoor installation since they interlock and stay together during temperature related expansion and contraction. However, the sub-surface needs to be properly prepared.

When installed outdoors, concrete, asphalt, and compacted stone are the three most popular sub-base materials. Prinz said the ground needs to be properly prepared before paver installation, otherwise settling will occur and usually result in sinking. “If the sub-base starts to sink, so will the rubber tiles as it will follow the contour.” For temporary installations, Prinz said installers should first compact the ground and then cover it with a fabric/mesh. The pavers should then be installed on top and the interlocking joints glued with the company’s Chemrex 948 urethane adhesive.

For a more permanent outdoor installation, perhaps as a patio or under a pergola or pavilion, the ground should be prepared with 3”-5” of compacted stone, covered with the mesh/fabric, and then topped with the pavers. Again, the pavers should be glued for stability. If additional drainage will be needed, the pavers can be drilled easily (from the bottom, between the cones) and water will drain more effectively.

Maintenance Advice

Tell your customers to keep it clean. If your client decides to install Unity or other rubber-based paver, they should follow some basic maintenance guidelines to get the best performance from their pavers. Printz advised, “As with any other solid surface such as concrete or asphalt for outdoor usage, Unity’s products will need to be cleaned of debris.” If used outdoors, pavers can be cleaned with a leaf blower; if used indoors, a regular shop vacuum works well.

A ‘Permanent’ Solution

Unity products are durable: “There’s no weight limit,” Prinz said. “The material holds up well under hundreds – sometimes thousands – of pounds per square inch. We do weight rooms and the stacks of weights don’t hurt it.”

They can be expected to last up to 20 years. If under heavy foot or equipment traffic, or if the pavers aren’t cleaned properly after spillage (hydraulic fluid, for example), tiles would need to be replaced more frequently. However, the way the tiles are designed, worn-out or damaged tiles can be removed and replaced without having to replace the entire floor.

When glued and/or screw-anchored, the pavers should be considered permanent. They’re not going to move. When they wear, they can be painted. “We provide the necessary paints that can be sprayed on or simply rolled on for a brand new look,” said the company.

“This application can provide less heat build up and extend the life of our products for many more years to come.” GCSB