The delivery of an investment, whether a shed or other building, to the location of choice has several variables to take into consideration. Expert guidance and operation of machinery by professionals is going to be on the minds of all in the project, especially those who hire for the job.

Steve Borntrager of Cardinal Manufacturing and Reuben Miller of Pine Hill Trailers explain the general practices of planning and operation of delivery equipment by the pros, and what all involved need to understand before, during and after the critical phase of moving a shed.

GSCB: What are the most important factors to know before choosing the correct trailer and Mule for a shed-moving project?

SB: First you should consider what size sheds you will be delivering, and make sure you choose the correct Mule for the size shed you will be moving. Also, what kind of terrain will you be delivering in? If it’s mostly on hard surfaces you will want to consider a wheel model or, if mostly on soft, muddy, sandy terrain, a track machine would probably be a better option.

GSCB: Why should companies use shed movers and trailers?

SB: The biggest factor will be time efficiency. You can be in and out much more quickly, which allows more deliveries per day. With a Mule, you are able to use larger trailers and haul multiple buildings simultaneously, because the trailer never has to leave the road or be maneuvered into a homeowner’s yard. Also, there will be minimal disturbance to the homeowner’s yard compared to driving a heavy truck and trailer into a yard, and you have the ability to put a shed almost wherever a homeowner has room for it, compared to being restricted to locations that are truck-and-trailer accessible. The traction and flotation of the Mule gives you the ability to transport sheds across muddy or sandy terrain where trucks and trailers could never go. Depending on your locality, using a Mule substantially extends your hauling season because it’s possible to start sooner in the spring and deliver later into the fall because of being able to navigate wet and muddy conditions. Not to mention utilizing most up-to-date and capable delivery equipment will improve your company’s image.

GSCB: When do they have to make this important decision in the shed-moving process, and the planning/steps?

SB: Typically, immediately after deciding to deliver buildings and when making decisions about obtaining equipment. Homeowners will expect delivery personnel to have a Mule and will be disappointed if their shed cannot be placed where they had planned, so it is of ultimate importance for delivery personnel have one available. Start by obtaining information and pricing from the manufacturer or one of its dealers, and asking questions as to the recommended model for the application.

GSCB: What are the most common delivery/transporting problems facing shed haulers using the equipment?

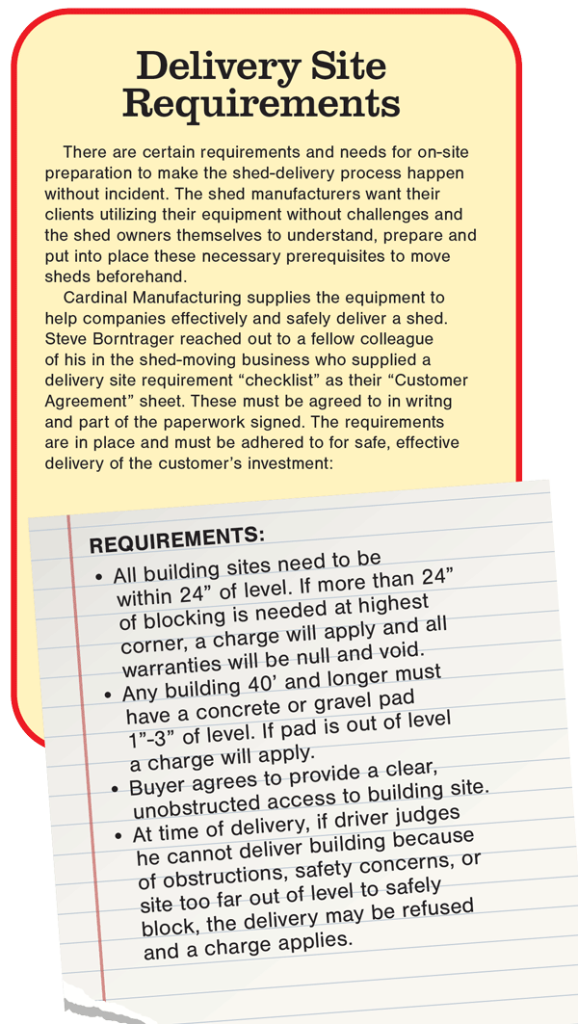

SB: I would say, inadequate preparation for sheds by the homeowner. When your delivery path and sites don’t have adequate space for maneuvering and placing your shed, such as tree limbs not being trimmed or the delivery pad drastically out of level.

GSCB: How have the challenges facing shed haulers evolved over time?

SB: Buildings continue to keep getting bigger and heavier, so bigger machines need to be designed to meet the demand.

GSCB: Cardinal and others have an R&D team. What is the process for testing and developing the right equipment with the most efficacy?

SB: Customer feedback and feature requests are our No. 1 driver for improvements, and we highly value the feedback we receive from customers. Our initial designs, as well as stress testing of parts, are done using 3D CAD software. Next, we use accelerated fatigue testing to ensure reliability of design and components and, lastly, we test R&D machines on actual delivery trucks in real-life situations.

GSCB: What are other aspects of using the right products, correct company and equipment for the job, that shed owners should know?

SB: Make sure you choose a shed-moving company that has the proper equipment and permitting for your job.

Trailers

The trailer plays a vital role in shed and other small-building transfer/delivery. Reuben Miller of Pine Hill shares his insight:

GSCB: What are technical aspects and challenges of moving a shed with the trailer?

RM: There are navigations of houses and trees. If you’re going back around a house, what if the ground is sloping toward the house? All of a sudden, the barn [or shed] – if you’re navigating a side hill – is not straight up and down and is parallel to the hill, it interferes with the house, the tree. Our trailers can tilt side to side to make that barn upright, to now navigate that turn. Trailers can make a building upright, parallel to the trees and house. Trailers can also lift a building up high enough to clear a fence. Now you can back through the gate. A shed hauler’s life – every day is different. There’s always something different to navigate.

GSCB: What are other maneuvers and accessories with trailers?

RM: Trailers can go sideways: There’s wheels underneath the trailer, they go down, they lift the trailer and the load and “walk you” around and turn – that’s a huge thing, the sideway wheels. There are barn-spinners: You have a 12’ x 16’ garden shed that you delivered. The driver gets there and the door’s on the wrong side. You slide the barn (or shed) back underneath the barn-spinner, you lift that barn, walk the barn around in a 180-degree turn and you drop it back down on the trailer. Now the door’s on the right side. Or, a 12’ x 16’ and the door’s on the side and they want it backed up against the fence, after it’s finished the door was supposed to be facing the truck. Now you can take the barn-spinner, give it a quarter-turn, put it back down and push it off the trailer. All are accessories to the [Pine Hill] trailer: sideways wheels, leveling axles, barn-spinners, chain drive, side-shift tail.Also, shed trailers [should] have a good tie-down system built into them to hold the sheds on to the trailer.

GSCB: Are remote controls essential?

RM: Every shed trailer needs to have a remote control. The trailer is used to level the building. Sometimes the driver will be inside the building [shed] with the leveler and remote, and you’ll be leveling it while the trailer is handling everything. It’s how people get the job done.

GSCB: How do you decide how the trailers should be built?

RM: We don’t just build trailers; we also fix trailers. We see all the possible problems that happen when trailer manufacturers don’t use quality products. When we started manufacturing trailers we were committed very early in the game to use nothing but the best. We go to a lot of trade shows to figure out what components [to select]. We are always on the lookout if there’s something better. Paint is a big deal. Many manufacturers don’t “blast” their trailers. All of ours are blasted to get rid of any oils, dirt and mill scale. Our blasting and coating process helps prevent corrosion when exposed to road salt. Blasting is very important.

GSCB: Any advancements to the trailer we’ll see for operators?

RM: Recently, the biggest request for innovation is the ability to haul larger buildings, 18’ x 70’, two- to three-bedroom homes. That’s becoming regular. As far as navigation to get a small building into a backyard with a trailer, that part is probably about as far advanced as it’s going to get, without using a helicopter. GSCB