By Linda Schmid

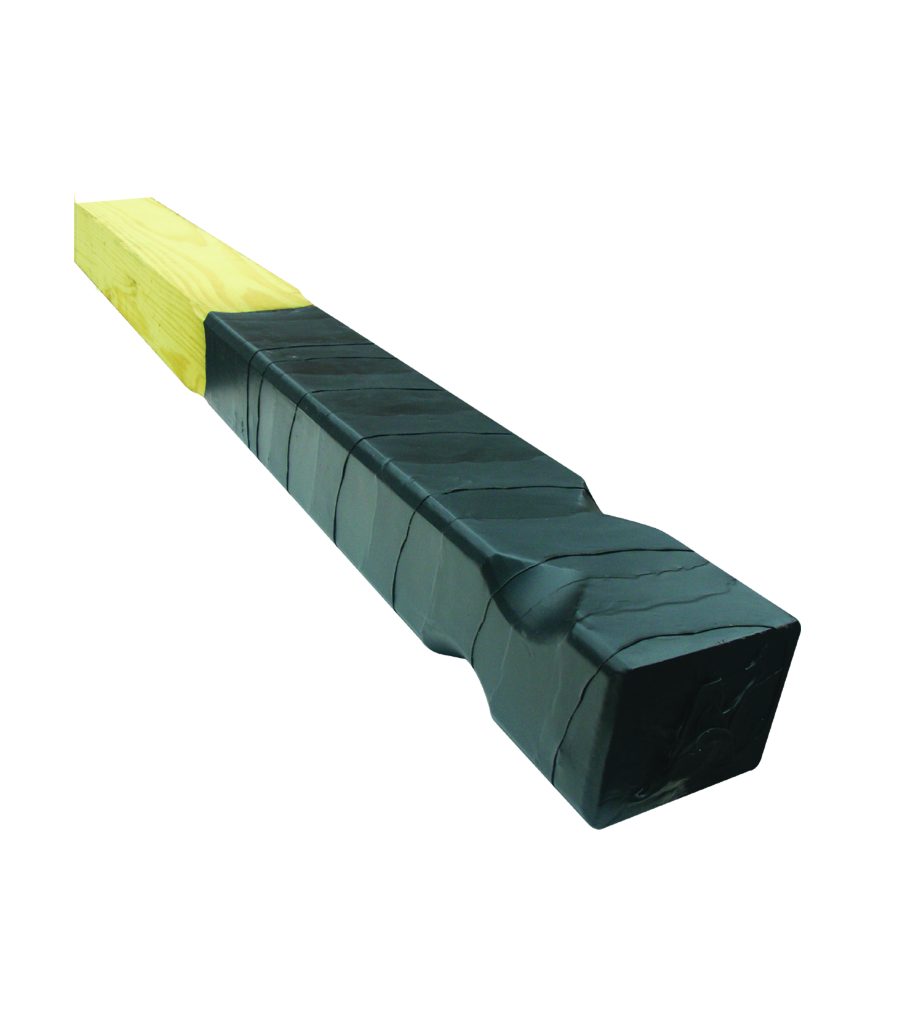

Green Post by Planet Saver Industries started out as Post Saver USA, a company that had developed a double barrier of waterproofing and polyethylene to protect posts for post-frame construction, as well as decks and fencing, from rot and decay when posts are sunk in the ground. In 2008, the company became Planet Saver Industries LLC. Around 2016, Daniel Lapp, the current owner, realized the value of post wrap and acquired the company.

Barry Hoffman was one of Planet Saver’s first customers, and he believed in it so much that he became an employee, and today he and Mel Lapp run the company.

Hoffman believes that effectiveness and product awareness, pure and simple, are what caused the company’s success. In some regions, people are concerned about placing treated posts in the ground because the chemicals can be toxic and can leach into groundwater. Hudson Valley, New York, is an example. The Hudson Valley is the well-spring of New York City’s underground water supply, so they did not want anything leaching into the water. Therefore, there is special financing available for agricultural businesses who use Green Post as part of their post frame buildings.

Green Post is now the signature product of Planet Saver Industries, and it works like this: Posts are waterproofed with a bitumen emulsion and wrapped in polyethylene that is heat-sealed onto the post so it is practically inseparable from the post itself.

When Green Post was getting started, the company was using manual processes for certain stages to apply the double barrier. Hoffman and his wife used a prototype machine to apply Green Post, loaded them on the trailer and delivered them. Over time, about 16 years, the company designed, developed, tested, and tweaked the machine, and they have created the Super-Winder. This automated machine now yields up to 45 Green Posts per hour.

The majority of their Green Post customers join an ASO program (Application Service Only). The builder/supplier has their posts sent to the applicator to have the GreenPost barrier applied. This is the most cost-effective way to work this out because warehousing of 15 different kinds of posts is not required by the applicator. Further, many of the suppliers receive volume discounts on their post purchases, so this process is the most cost-effective for everyone.

The company is located in New Holland, Pennsylvania, with application machines currently in Pennsylvania and Ohio, which allows them to cover half the USA. As well, Postsaver and Polesaver Sleeve — post solutions that can be applied to posts in the field — can go anywhere across the country, and are used where Green Posts are currently limited by shipping.

Customers purchase the Side-Winder and set up their own facility to provide Green Post barrier wrap to suppliers, builders, and contractors in their area, building their own business. There are two in the field and a few more are currently under consideration.

Hoffman says this is their business model. When someone buys a machine, they agree upon a territory so that suppliers do not have to compete with each other, then they support them in marketing their services and assist them in developing a healthy business.

However, that is not their only avenue of growth. Marketing is a big help as well. Hoffman says there are constantly more builders and contractors using Green Post, and there are more and more engineers specifying them.

The company’s success is no doubt also because of the company’s business philosophy.

“We want to form relationships with people who care about quality and service,” Hoffman said, “people who value what we bring to the table. We want to support those people to the utmost making it a heathy and profitable relationship.

“Knowing the investment of time and resources I went through, I would not encourage anyone to get involved if I didn’t believe it would work for them.

“Approaching people with honesty, respect for the individual, and understanding how we can help them succeed … these are the foundations we lay for business partnerships.” GSCB