Part 2 of a 2-Part Series

by Jamie White, PPG Segment Specialist

Are you wasting paint? Raw material costs have a heavy effect on the bottom line of any manufacturer. In our last issue, we discussed two of four simple ways to help improve the efficiency of your paint process: Correct Spray Tip Size and Fluid Pressure Settings. In this issue, we will discuss Using Proper Spray Techniques and Spray Gun Extensions.

There are many techniques used to apply a coating to a shed. Ultimately, as long as the finished product is acceptable, then you have accomplished the finishing goal. However, that does not mean you were efficient in doing so. What if you could get that same acceptable appearance, but use less paint and take less time?

When applying coatings to a shed with an airless or air-assisted airless sprayer, there are five basic principles to follow. These steps will allow you to use less paint, reduce your painting time per shed, and get a better finish. They are as follows:

1 Proper Distance from the Part: Spray tips are designed to give their best performance roughly 12” from the part. When held too close, the finish will be too heavy. When held too far away, the majority of your coating will not make it on to the shed. Proper gun distance from the shed will result in the best finish possible.

2 Correct Speed: There is not one set speed to properly apply coatings to a shed. Each painter will spray at different speeds according to their experience and/or training. If the painter moves too fast, they will not get enough coating on the shed and will have to repeat the process in order to get the required appearance. Moving too slow will result in excess coating being applied and the chance for paint runs that will need to be corrected.

Incorrect painting speed will cost time and/or paint. You want to find the right speed for applying an even coat at 12” from the part with the proper tip size. It can take some practice, however it can have a significant effect on your efficiency.

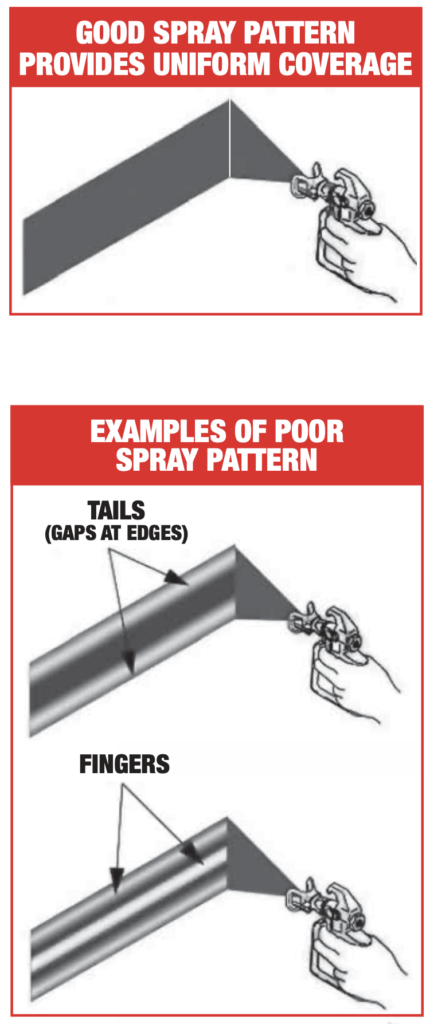

3 50% Overlap of Spray Pattern: Most sheds are painted with a vertical spray pattern (painting up and down motion). After the painter makes their first pass, move over roughly 50% from the previously painted surface to make your next pass. By overlapping, you will achieve a more even coat. If you do not overlap, then you are susceptible to getting light spots or even stripes in your finish. These can require additional coats to correct. If you are using a semi-transparent coating, the 50% overlap is critical to getting a consistent look. This overlap is also key when using a coating designed for one-coat coverage.

4 Bending Your Knees: To maintain 12” from the surface at all times the painter should be bending their knees. We see painters standing stiff and just moving their arms. This will cause your coating to be heavy directly in front of the painter and light above and below them. By bending knees, the painter will produce a much more uniform coating on the shed.

5 Using a Spray Gun Extension: The last aspect to achieving an efficient, acceptable paint job is using a spray gun extension (wand). This is a very effective tool that we unfortunately do not see enough shops utilizing.

Spray gun extensions come in different lengths. Although extensions are available from 6” – 144”, the most common lengths are 10” and 12”. The extension attaches to your spray gun where your tip guard normally attaches, with your tip and guard attaching to the end of the extension. This allows your painter to ensure the gun and tip are pointed directly at the building when they are reaching up to spray high points on the walls/gables or pointed down to spray the lower portions. They can also reduce the amount of time needed on a ladder (and increase safety) because you can now spray from the ground. When you do not use an extension there is a tendency to try to reach portions of the building from too far away, causing paint to go into the air and not on the part. (Note: spray gun extensions are not available with air-assisted airless sprayers.)

Applying the above five principles will give you the opportunity to increase your painting profitability. Please reach out to your local PPG Paint Specialist to further discuss painting tips. GCSB

To better understand how to get the best coatings system, contact Jamie White ([email protected]), who will put you in contact with a PPG Truefinish Specialist in your market.