By Linda Schmid

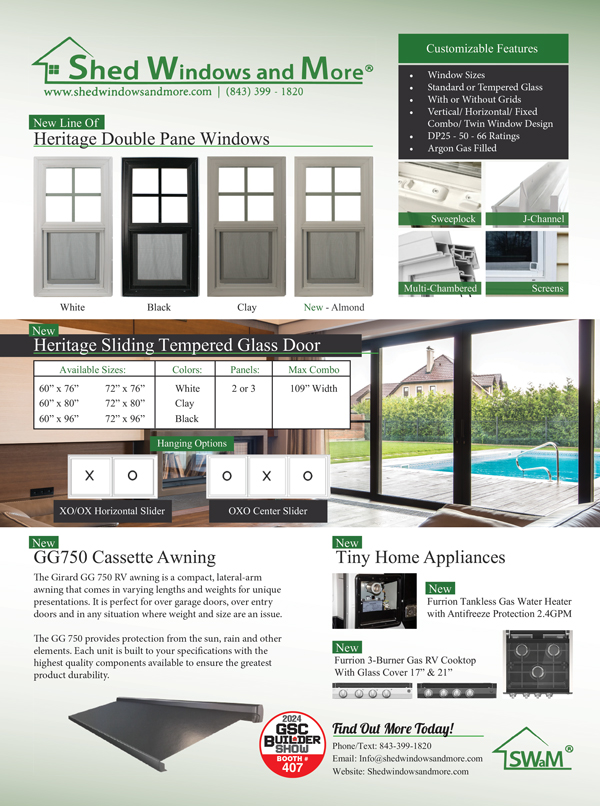

Some ideas are just so right that people ask, “Why didn’t anyone make this sooner?” Lin Warner says that is what people ask about the SteelGrip SAMM Mat. Lin, Administrator, and Neil Warner, CEO, are the founders and principals of SteelGrip SAMM.

An Idea That Drew People In

Neil and a partner ran a painting business, and they discovered that they were spending man-hours creating scaffoldings to reach dormer windows three stories up. They were sure there must be a better way. They developed the initial idea of magnetic mats and when Neil said they should market it, his partner opted out. Neil forged ahead.

That lead to 5½ years of R&D with each component scrutinized and tested extensively, in the field and by a third party who did 1000 hours of weather and stress testing. Formulating fabric, magnets, and design led to developing SAMM (Safety Assist Magnetic Mats), a product that would work on many types of steel. Of course, with this much time spent on a product that was not yet salable, financing could have become an obstacle to success. However, people Neil knew from the local business community and his former painting customers believed in him and this unique safety invention and lent the fledgling company money.

The answer to the question we started with, why did no one make this sooner, was answered during the R&D phase. The materials that make this product so reliable, the magnets and fabric, weren’t around until recently. The mat’s components are themselves products of advancing technology.

The final designs offered mats that won’t move unless you intentionally grip the corner and lift toward the center of the mat. This provides roofers with surer footing and relieves the tension workers often experience in their back and legs as they brace themselves on pitched roofs. These mats provide a place to set the tools needed to perform a job while preventing tools from sliding off the roof and scratching the panels as they go. They even work on wet roofs. Having tools at hand reduces trips up and down the ladder, a true productivity killer.

In 2019, the SteelGrip SAMM mat became available with mats for pole barn and standing seam style roofing. The Warners stayed in contact with contractors and began selling to them. The mats are used by roofers, painters, solar installers, pest control, chimney cleaners, masons, equipment washers, homeowners, and firemen. One guy even started using them on the fender of his car and under the hood to hold his tools while doing engine maintenance!

Pulling In Sales

Early on, orders overtook production as Lin and Neil were cutting fabric off large rolls to hand-glue the mats. Then they began modifying equipment they had to make it work for their purposes. For example, they modified jigs for glue application and screen printing equipment. Now they work more efficiently using a CNC for glue application. They are ready to ramp up sales.

The majority of sales have been through word of mouth, Facebook and internet searches leading to the website. They are now actively shipping to 49 states (only missing Nevada for sales) and Canada from their headquarters in Elk Rapids, Michigan.

What’s New!

In 2023, the company introduced the new SAMM PRO mat that will conform to every style of steel roofing including pole barn, standing seam, corrugated, and architectural. The neodymium magnet, or rare-earth magnet incorporated into this mat is even stronger than the original. It is so strong that part of the testing included coating a 7/12 pitch steel roof with Vaseline. The mat did not budge. One restaurant roof-cleaning company uses it to stay in place while cleaning off the cooking grease expelled from roof fans.

Positive Attraction

So far the company has operated with a shoestring crew: Neil, Lin , and brother-in-law Glenn who sub-contracts with them. But the plan is to hire positive people and open offices in various locations around the country. The Warners say that the company culture is positive and upbeat, and they believe that new employees will be drawn in when they see the pride they can take in producing a quality, long-lasting product that helps keep people safe. They want their new employees to learn every piece of the business from assembly to shipping to tracking.

SAMM’s tagline is: “If you’ve got the grit to work on a steel roof, you need the grip to keep you there.” Roofing is the fourth most dangerous job in America. Neil and Lin wish to extend their deepest respect to roof workers who literally help keep everyone sheltered by putting a roof over our heads.

The Warners are proud to support the steel industry with a safety product that not only makes jobs easier for workers, but increases productivity. The fact that recyclable steel roofing is growing in popularity “is a win/win for everyone,” Lin said.

Stick-to-it-iveness

Neil’s advice to anyone in the industry who is treading the hard path of testing, development, and marketing of a new product is persistence. In fact, he suggests reading the book, “Irrational Persistence” by Dave Zilko. When developing a new product, he said, ask yourself if it solves a problem, have people try it, listen to their feedback, and make the changes needed.

“Your goal,” Neil said, “is the highest quality you can produce, a product of substance created with quality materials.”

Beyond this he advises educating yourself as much as possible; attending business seminars, legal seminars, whatever you have access to. An education is needed to produce a good product.

The Future

Neil and Lin’s goal is to grow the company nationally, but internationally, too! They believe it’s possible because they have a great safety product that partners well with the steel roofing industry which is growing due to its durability, recyclability, and survivability during many natural disasters. Steel roofing is now available in just about any style, texture, or color you could want as well. It’s a great time to support the steel roofing industry! GSCB