Are All Garage Doors The Same?

by Karen Knapstein

All garage doors share one purpose: to securely close off the large openings in garages and other sheds to keep what’s inside safe. Where you find the differences is how they operate, how good they look, what kind of insulation value they have, and a few other considerations.

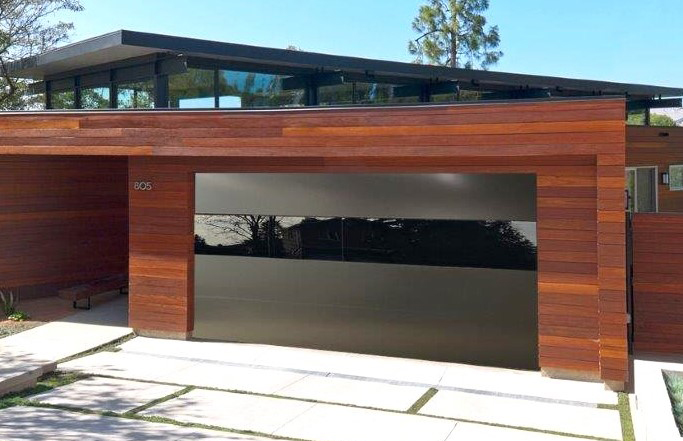

A modern look: Regency garage doors in Madera Black with Contempo glass.

Courtesy of Safe-Way Doors

This photo shows how important door selection is. In this case, it’s the first thing seen from the street and strongly impacts curb appeal. Courtesy of Safe-Way Doors

Billy Thompson, vice president of sales for Safe-Way Doors, explained the basic types of garage doors, how they work, and the applications of each type. His company has a wide variety of products, from entry-level doors to high-end residential doors. He explained that choosing the right garage door depends on what the owner’s architectural requirements are and what they’re trying to accomplish with their building. Are they choosing a door for a standard, catchall shed? Or are they aiming for more curb appeal?

Sheet Doors

At the lowest end of the garage and shed door design spectrum is the sheet door. Often called “roll-up doors,” “coiling doors,” or “rolling service doors,” sheet doors come in a simple corrugated design and roll up onto a drum when opened. Sheet doors are very utilitarian: They get the job done, but there’s not much design choice. “[They’re] pretty commercial,” Thompson said.

Trac-Rite Doors [www.tracrite.com], a division of Trachte Building Products, is one of the world’s largest producers of self-storage building systems. Based in Sun Prairie, Wisconsin, and 100 percent employee-owned, Trac-Rite has been producing doors since 1981 and has recently expanded its facility. Steve Hajewski, marketing manager with Trac-Rite Doors, said the expansion added a new forming line and robots that now make many of the doors.

Highly functional sheet doors are mainly used in self-storage units. Trac-Rite Doors offers 16 different colors.

Courtesy of Trac-Rite Doors/Trachte Building Products

Trac-Rite receives coil steel that’s coated with siliconized polyester paint and they roll-form the steel to form the ribs. The corrugations, the track mounting, and the bottom bar all contribute to the high wind rating of this company’s doors. In fact, Trac-Rite’s base model 944 sheet door has a wind rating of 130 mph on a 9′-wide opening. The company manufactures doors that measure from 3′ x 3′ to as large as 16′ x 16′.

While sheet doors are primarily used in self-storage applications, they are also used for sheds and garages, Hajewski said. Shed makers, he explained, tend to stick to the Iced White color for economies of scale. He said it’s common to use all white doors and add pops of color by painting the walls or adding colored shutters.

Trac-Rite does offer its doors in 16 different colors. Hajewski said years ago, sheet doors were primarily manufactured in bright, gaudy colors. It seemed like all storage units had them. “There’s been a huge shift in color preferences,” he said. “One of the most popular colors recently is Shale, which is a nice, neutral, almost grayish-tan color that’s been immensely popular.” He said black has been popular, too. “When people saw how classy black doors look on a tan building, the color has taken off.”

Another improvement of sheet door construction in recent years can be seen in the door springs. Hajewski said old self-storage doors would have problems with the coils rusting together and the springs would break. Around 2006, Trac-Rite switched to using a coated EP3 spring that includes a rust-prevention coating. He said some door manufacturers alleviate the problem of rusting springs by applying a thick coat of lubricant, but Trac-Rite prefers the EP3 spring: “It’s not messy and it seems to have greatly extended spring life.”

The advantages of installing a sheet door include cost effectiveness and easy installation. Plus, sheet doors require less head and side room. For Trac-Rite roll-up doors, only 2″ of space on the sides of the opening are needed for door jambs in metal or wood-framed construction, and only 4″ of space are needed for masonry. Depending on the size of the sheet door, as little as 15″ of head room is necessary for the door installation. (The larger the door, the larger the drum that the door rolls onto, and the more head space that is required.) Sheet doors maximize the space inside.

Adjusting the tension on a sheet door is another advantage. “Dealing with the tension on a sectional door can be a little scary,” said Hajewski. “But on roll-up doors, it’s usually a pretty simple ratcheting mechanism.” When you install a roll-up door, to put tension on the spring, you wind it a few times against the coil. To adjust the tension, it’s a simple matter of turning the ratchet wheel located at the end of the drum.

Sheet doors are easy to install, Hajewski said. A do-it-yourselfer and a buddy can install a roll-up door in about 20 minutes. On the downside: If a sheet door is damaged, you have to replace the whole door since it’s a single piece (you can’t just replace a section or two). Sheet doors also have low thermal value and you don’t have any design options. “If you’re installing on a heated or cooled building, you’re going to want to use a sectional door,” Hajewski advised.

Steel Sectional Doors

Safe-Way Doors [www.safewaydoor.com] is a family-owned company headquartered in Warsaw, Indiana. The company is a leading manufacturer and distributor of residential, commercial, and industrial overhead garage doors.

Company vice president Billy Thompson said one big advantage of sectional garage doors is there are an abundance of panel options. If made of steel, the steel can be stamped with any number of design details. There are also thermal considerations.

Thompson said there are only a few types of residential steel sectional doors, and their insulation value varies widely.

All sectional doors fall under these types:

• The pan-type garage door has an open back and no insulation. The door is comprised of hollow-formed steel sections connected together. Pan doors have no R- or U-value; these are generally the least expensive type of sectional door.

• A pan door with a vinyl-back insulation insert has an R-value of 6.00.

• A three-layer steel-back door with a steel front and back and a polystyrene core has an R-value of 10.25.

• The door with the greatest insulating value is the three-layer steel-back door with a steel front and a polyurethane core, which has a 17.68 R-value.

When considering what type of panel garage door is appropriate for a project, Thompson said you need to base the decision on what the owner is trying to accomplish with their building. Is it a standard shed? Is it a catchall? Is it a “she-shed”? Or are they looking for added curb appeal? He recommended one first determine the goal of the building, and then look at what options are available. Establish the functionality, then consider what the owner is trying to accomplish architecturally.

Safe-Way manufactures doors from very basic, functional commercial doors to high-end residential garage doors suited to please the most discriminating tastes. They offer wood, insulated and non-insulated steel, raised and flush panel, aluminum, and carriage house-style overhead garage doors in both steel and wood varieties.

Thompson said the sky’s the limit when it comes to sectional garage door design. He said there are Safe-Way doors that achieve whatever look the owner is striving for. Full vision doors give a more contemporary look, but there are also carriage house doors, more traditional-looking overlay-type designs (doors with crossbuck designs stamped in the metal), columns, arches … with the ability to stamp designs into the steel, and many long-lasting finishing options, the possibilities can be overwhelming.

Each type of panel door can be customized through design details and different glass options. Safe-Way Door uses at least double-strength glass in all of its doors. Sometimes it installs ½” insulated glass, or ½” insulated tempered glass, but the minimum is double-strength glass. Ultimately, it depends on the application and what the architects and home or building owner request.

Builders should guide their customers first to function, then to form. But remember: Don’t let the building owner try to put off choosing their door; it has to be a part of the design and planning process.

Fiberglass Sectional Doors

Kevmar Manufacturing [www.kevmarmfg.com] is a regional, family-owned manufacturer of garage and shed doors that sells directly to shed builders. In the garage door industry since 1986, they deliver in the Midwest and South, and ship LTL to other locations. Willis Miller, an owner/partner, said Kevmar has been producing garage doors since 2004. They began making molded fiberglass garage doors in 2007, and in 2017, they introduced their line of shed doors, which “have been well accepted within the industry.”

“The shed industry is a vibrant industry and very good to work with,” Miller said. “Delivering smaller, more basic doors to shed builders allows builders to purchase not only pan-type doors, but the rest of the Kevmar product line, as well.”

“One thing that’s changed a lot in the industry — much like the post-frame industry — is the color selection,” he added. “Initially, white was about it for color for steel garage doors. Kind of like the post-frame business, colors and designs have grown exponentially in the last 10 years or so. Color and design of garage doors is becoming much more important.”

Kevmar steel doors are available in unique panel designs and five colors. The Kevmar insulated steel door offerings include a 2″-thick urethane-filled door in a commercial or post-frame version and a residential version. The company’s current maximum door size is 18′ wide x 14′ high.

Miller said they also offer a line of high-end molded fiberglass doors. The fiberglass is molded to replicate a conventional wood door with deep panel profiles and wood grain. They are available factory stained or painted, and they are also available unfinished. He said fiberglass is an excellent material for manufacturing garage doors because they can be molded with accurate detail compared to steel: “It’s very precise and predictable.”

He said Kevmar doors are “extremely dent-resistant” and available in an optional Stormguard version certified for wind speeds up to 130 mph for coastal, hurricane-prone areas. “Fiberglass insulates better than steel and will never rust,” he added.

A recently added model is a smooth, flush steel door that is available in 35 colors, including Western Rust and Galvalume. “The entire window section in this model is all glass and frameless,” Miller explained. “The exterior looks like a single sheet of black tinted glass. The glass is tempered and very impact-resistant.”

Miller said the most dangerous aspect of installing sectioned garage doors is winding the torsion and tensioning springs. “Follow the manufacturer’s instructions,” he advised, “and it should be fairly easy and safe to do with a minimal amount of experience.”

Regardless of whether a sectional garage door is made of steel, wood, or fiberglass, the “pros” of selecting a sectional door include: more panel designs, more window and architectural options, greater curb appeal, and they can be more durable. Plus, if you damage sections, you can replace only those damaged sections; you don’t have to replace the entire door as you would with a sheet door. Also, insulated garage doors have very good thermal performance, which will save your customers money when enclosing a heated or cooled space.

The cons include: Sectional doors require more head and side room, they are more complicated to install, and they cost considerably more.

In the end, when deciding on a door for your shed project — whether it’s a she-shed, man-cave, garden or machine shed — you need to first consider the purpose of the building. GCSB