When people talk about paint systems, such as fluoropolymer resin-based coatings, they are referring to the resin system incorporated in the paint. This resin system determines the properties and performance of the paint. The breakdown of a typical gallon of liquid paint is 10% pigment and 20% resin in a 70% solvent base.

Liquid coatings are made with solvents that contain VOCs. The VOC content is off-gassed at the factory before materials are delivered to the jobsite.

Choosing Paints

There are many paints used in metal construction. They include alkyds, urethanes, acrylics, epoxies, polyester hybrids, polyesters, siliconized polyester, urethanes, and polyvinylidene fluoride (PVDF) formulations.

All of these formulations have their place; for every project there is a balance between performance and price. Other considerations when choosing a paint for architectural building products include climate, condition, and use of the building.

Often polyesters will work well for sheds, while silicone modified polyesters (SMPs) are commonly used for agriculture and utility structures. Residential projects are often completed with PVDFs and some SMPs. PVDFs are ideal for commercial and architectural exteriors, also.

PVDFs are recommended for exterior use only. While SMPs may be used inside, they are usually used on exterior surfaces.

Polyesters or SMPs are often the paint system of choice for metal coils used in sheds, agriculture, residential and commercial buildings.

A summary of what’s popular, by structure type:

• Sheds: Polyesters.

• Ag and Utility: SMPs.

• Residential: PVDFs.

• Commercial, Architectural: PVDFs.

• Metal Coils: Polyesters or SMPs.

Choosing Roof Coatings

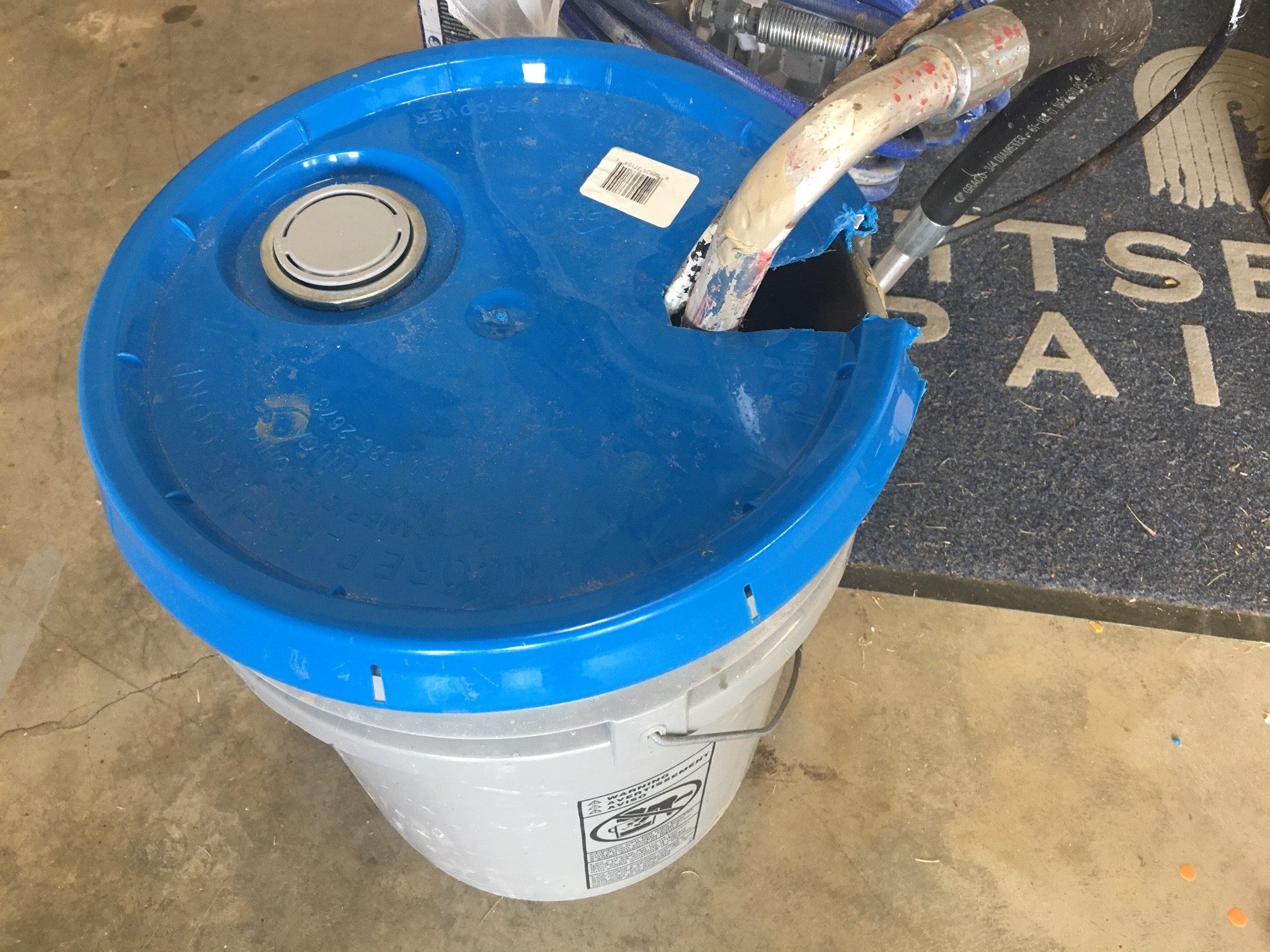

Metal roof coatings create a whole new waterproofing substrate on the roof with extra surface protection. They come in four basic chemistries: liquid rubber, silicone, acrylic, and polyurethane.

Liquid rubber is arguably the most popular as it has great adhesion, UV reflectivity up to 87%, and corrosion inhibitors. It’s air-cured so when it’s in sprayer lines, you can stop spraying, go to lunch, come back and start from where you left off. It is flexible and advantageous in climates where the weather vacillates between hot and cold causing metal to expand and contract.

Silicone is a seamless, breathable membrane that seals against leaks and severe weather. It provides high solar reflectance and UV resistance for lasting strength and performance.

Acrylic is easy to apply and has great UV protection. In fact, this roof coating was originally developed specifically for roofing materials.

Polyurethane has high impact-resistance and is great for withstanding pooling water and a lot of foot traffic.

In addition, formulations and application methods can vary, so before choosing a coating, examine the manufacturer’s material data sheets to determine which product is the best match for your project.

Preparation for Paint

A quality metal paint job always requires preparation. It is estimated that around 80% of coating failures are due to improper metal surface preparation. The surface must first be well cleaned; any extra material left on the metal may be a deterrent to good paint adhesion.

The next step is chemically pretreating the substrate to help with adhesion and add extra corrosion protection that paint alone cannot provide. Zinc phosphate is generally the pretreatment of choice, unless cost is the overriding consideration, in which case iron phosphate may be used.

Finally, primer is required for most paints. Galvanized or other rust-inhibiting primer is the best choice.

Metal preparation and painting is often done in the factory where the environment is controlled and the best outcome is possible. Proper pre-treatment includes cleaning, chemical treatment and usually primers, which stabilize the surface and improve adhesion. Pre-treatment steps may include:

• High temperature acidic solution rinse for cleaning

• High power clean water rinse

• Amorphous chromium phosphate conversion coat serves as a primer and improves adhesion and rust resistance

• Neutralizing clean water rinse

UV & Weather Exposure

Ultra violet rays penetrate nearly every surface, and this excess energy causes degradation. Painted surfaces have no way to emit the captured energy and it begins breaking down the pigments and bonds that hold the paint resins together.

UV exposure can affect:

Gloss retention: A paint’s ability to reflect light without scattering can be diminished by UV exposure causing loss of luster.

Chalking: As the resins break down, the particles take on a white hue and pigment particles lose adhesion.

Fading: The UV radiation dries out the paint, causing discoloration and leaving the substrate beneath unprotected.

Blistering: Loss of adhesion caused by heat, moisture or both, causes paint to lift up from the surface, peeling and corroding.

Cracking: As the paint resin dries up, it can lead to fractures in the paint which peels away from the surface.

For all of these reasons, it is important to check the recommendations of the manufacturer regarding the ability of a metal paint’s ability to stand up to UV exposure and other elements. In fact, test data on field performance should be available.

More Paint & Coating Tips

• Caution is advised in regard to adhesives. Check with the manufacturer to see if there could be a negative reaction between the adhesive and metal coating.

• Sealers are usually not required on pre-painted metal, but check with the manufacturer.

• Fasteners need to be compatible with the substrate itself.

• Acrylic adhesives are best for use with architectural aluminum as rubber adhesives can be difficult to remove.

• Environmentally conscious finishers capture and destroy the VOCs to avoid negative environmental impact. GSCB