Successful Business Springs From Personal Project

by Karen Knapstein

Cypress, Texas-based Arched Cabins is a family owned and operated business that has been building metal-ribbed buildings for the past 15 years. The crew includes father David, his wife Harmony, their sons Joshua and Jeremy, and Jeremy’s wife Gillian.

David Cruey invented the arched cabin. Once he built his arched cabin retirement home in New Mexico, and son Jeremy built his primary residence, also in New Mexico, people started asking how they could get homes like that, too. Long story short: Arched Cabins was born.

Jeremy explained, “The arch is based on the Gothic arches found all over Europe. The Gothic arch design is great because it’s strong and stable. It makes for a really great structure.”

The arched structures have really caught on, but not without a few pauses along the way. “When they were first introduced to the building market,” Jeremy said, “building departments had never seen anything like them before. We had to get all the structural engineering put through and approved.”

“One of the biggest challenges is getting into California because of all the building codes,” he said. “It’s just another process but we worked with engineers and the State of California to get them permitted in that area and they’ve worked out well as houses.”

The arched structures are incredibly sound. The company has shipped building kits to all 50 states and Jeremy said they’ve gone through permitting in every state. Their buildings have exceeded all of the 2019 Standard codes that they’ve come across.

Steel Strong

Arched Cabin kits are manufactured with curved ribs made from 2”x2” tube steel. They built a roll-forming machine themselves that creates a C-channel in the tubing to give the ribs more structure. The patented design has the ribs, spaced 24” apart, snapping in place in such a way that competent do-it-yourselfers can put the building kit together.

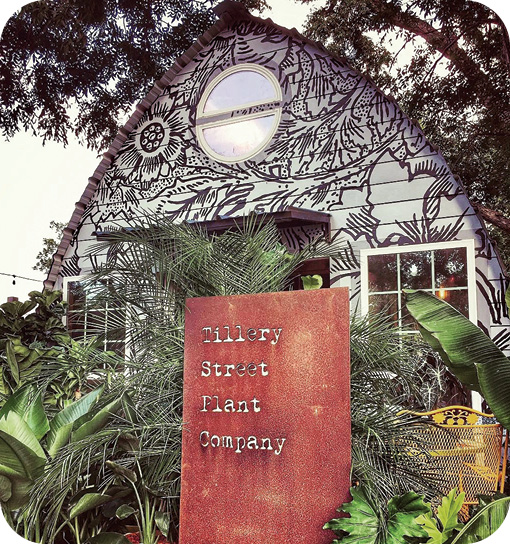

The unique shape of Arched Cabins structures lend themselves well for use as memorable shops, such as the Tillory Street Plant Company, Austin, Texas.

The exterior — MBCI’s 24” Superspan PBR panels in 26 gauge — are through-fastened to the ribs with color-matched fasteners that are provided. The PBR panels have a full lip overlap preventing leaks, drips, and seeps.

The standard panel finish is a galvanized finish with 20-year warranty; the upgraded panel option is finished with a proprietary polymer coating with a 40-year warranty. “Galvanized lasts a long time,” said Jeremy, “but it’s nice to have a color choice and it’s nice they give it a 40-year warranty.”

So far, the company has built thousands of kits and shipped them off to excited new homeowners. Kits include everything for the building envelope including standard R13 insulation. A detailed build manual is included.

In the past, Arched Cabins had a road crew that would travel and put the kits together. These days it’s up to homeowner to find a local builder and finish it out. “It’s much more affordable for people to find local builders,” said Jeremy. It makes it more affordable for them and more affordable for the customer.

What Builders Should Know

Arched Cabins builds kits from 8’x8’ in size all the way up to 30’ wide x 40’ long, and the structures can be built on any type of foundation. “Everyone is different with different needs,” Jeremy said. “The open profile of the Arched Cabin can be finished out any way you want. It can be super rustic to super modern. It lends itself well to any way the customer wants to finish it out.”

Those customers who cannot do it themselves will seek the help of local builders. “Standard construction practices will cross over into an arched cabin,” Jeremy said. “For the interior finish, sheetrock will curve up the walls. Half-inch sheetrock works fine. Most guys building in the industry will have the scaffolding, tools, and ladders and everything they need in order to finish it out,” he explained.

Plus the kits come with a comprehensive build manual and the company mans a help line. “Any time customers have questions they can call the office for help.”

Three Keys To Good Business

When queried about their Three Keys to Good Business, without hesitation Jeremy said: “Communication and support are number one. When you have a product that people aren’t familiar with, they appreciate that communication and support. Help them and they become fans for life.”

Their second key is affordability. Arched Cabins builds a component (the shell) that allows someone build a home for just $30-$60 per square foot.

Their third key is believing in what they do. “We’re not just showing up and trying to push a product that won’t be here in 5 years,” he said. “We’re selling a lifetime product that we all believe in.”

“In our market, tiny homes on wheels and modular tiny homes are often built with subpar materials,” Jeremy explained. “Tiny homes on trailers may be using 2x4s that are actually 1 1/2”x3”. They might be using quarter-inch sheetrock. The buyer might have a 30-year mortgage on their tiny home, but it may only last 20 years.”

“It’s amazing how excited people are about Arched Cabins,” he said. “We’ll talk with some customers for two or three years before they buy one. Every one of our customers is important. Whether they’re building next week, next month, or next year … you get the same quality service and support.”

Building A Future

What started out as a personal endeavor turned into a wonderful thing for the Cruey family. It also turned out to be a wonderful thing for the people and families who aspire to own their own homes. “The biggest focus for us has been the quality of life. It’s provided a better quality of life for us and for our customers,” Jeremy said. “It’s a way of life for us. And it’s a means for people with not a lot of means to have a home. We’ve invested in it and it’s been a really good investment for us.” GSCB